The Dalton Cumbrian Facility

Pioneering Research in Radiation Science.

The Dalton Cumbrian Facility (DCF) is the UK’s leading academic research facility dedicated to radiation science and nuclear engineering decommissioning. Operated by the University of Manchester, DCF provides a world-class environment where researchers from academia and industry collaborate to enhance our understanding of radiation effects on materials, systems, and components.

Our cutting-edge facility enables scientists to simulate decades of in-service radiation exposure within controlled conditions. This critical research supports the development of predictive models, informing the safe operation, maintenance, and decommissioning of nuclear power infrastructure.

State-of-the-art facilities and equipment

DCF houses an extensive range of specialist equipment for ion beam, gamma, and x-ray irradiation, alongside advanced analytical and characterisation tools. Our researchers have access to dedicated laboratory spaces, meeting rooms, and research offices, ensuring a seamless workflow from experiment setup to data analysis.

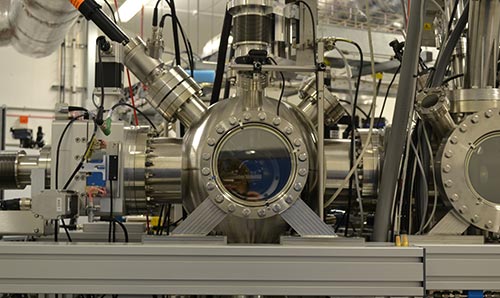

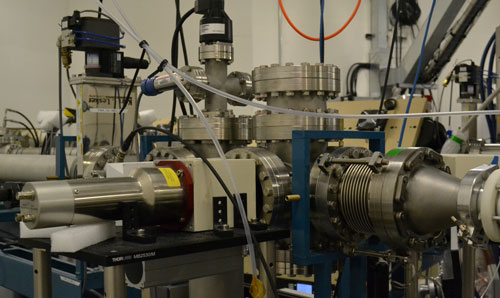

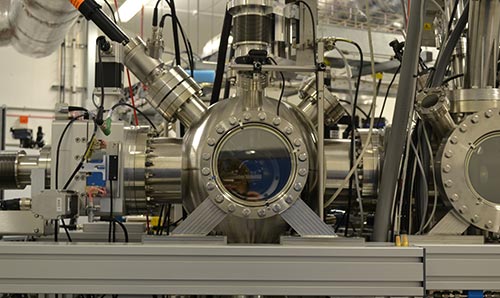

Particle accelerators and ion beam irradiation

At the core of DCF’s capabilities are two particle accelerators: a 5 MV tandem and a 2.5 MV Pelletron, configured to deliver ion irradiation and analysis across eight beamlines. These allow researchers to:

- Replicate years of radiation damage in a fraction of the time.

- Conduct tightly controlled, in-situ experiments to assess real-time material responses.

- Utilise dual ion beam capabilities for simultaneous damage assessment and radiation field exposure.

Please visit our research portal for more information about our accelerators and ion beam irradiation equipment.

Gamma and X-ray irradiators

For photon-based irradiation, DCF provides two complementary instruments:

- High-Dose Rate Gamma Irradiator – Capable of delivering dose rates from 25 kGy/h to below 100 Gy/h, this system supports research on gamma radiation’s mechanistic effects on materials and components.

- Precision X-ray Multi-Rad 350 Irradiator – Ideal for experiments requiring lower-energy photons, with dose rates of up to 24 Gy/min.

Please visit our research portal for more information about our gamma and X-ray irradiator equipment.

Analytical and characterisation equipment

Our comprehensive analytical capabilities enable researchers to investigate both materials science and radiation chemistry with precision. Key tools include:

- X-ray Diffraction (XRD) and Scanning Electron Microscopy (SEM) – Mapping texture and crystal structures of metals and composites.

- Raman Microscopy and Spectroscopy – Probing radiation-induced changes in polymers, glasses, and composite materials.

- Electron Paramagnetic Resonance (EPR) and Chromatography – Analysing chemical changes and radiolytic gas production in various materials.

Please visit our research portal for more information about our analytical and characterisation equipment.

Sample handling and specialist set-ups

DCF’s team continue to develop world-leading automatic sample handling capabilities, allowing higher sample throughput and safer irradiations. We encourage potential users to engage with us, as our team has a strong track record of finding innovative solutions to experimental challenges.

Radiation chemistry modelling

In collaboration with The University of Manchester’s Mathematics Department, we are developing a state-of-the-art radiation chemistry modelling toolkit. This advanced tool is designed to solve complex problems involving solid-fluid interfaces under irradiation. Researchers interested in using this toolkit are encouraged to contact Fred Currell to discuss potential applications.

Supporting innovation and collaboration

DCF offers an open research environment where visiting scientists benefit from expert support, access to world-class experimental infrastructure, and a collaborative network of leading academics and industry professionals.

By bridging the gap between academia and industry, the Dalton Cumbrian Facility plays a vital role in advancing nuclear science, improving materials longevity, and ensuring the safe future of nuclear technology.

Accessing our facilities

We welcome academic and commercial users from the UK and overseas. Information about the booking process for our equipment is detailed below:

Facility booking process

Accelerators and beamlines

Calls for beamtime proposals are usually published in early April, August, and December. Slots are allocated on a four-monthly basis:

- June to September

- October to January

- February to May

To receive notifications about calls for proposals, email dcf.experiments@manchester.ac.uk and request to be added to the Accelerator Users list.

Proposals undergo panel assessment, and we strongly encourage an informal discussion before submission. Proposals should be submitted on the most up-to-date form, which is emailed when calls are issued.

Process:

- Contact DCF for an informal discussion before submitting a proposal.

- Outline and agree on experimental activity informally, pending final confirmation.

- Submit the proposal form to dcf.experiments@manchester.ac.uk in response to a call.

- Proposal undergoes technical evaluation at DCF.

- Proposal undergoes scientific review and prioritisation. All potential users will also be expected to review proposals.

- Facility time is allocated based on availability.

- Experimental activity is scheduled, and confirmation is sent to the user.

Gamma and X-ray Irradiators

Calls for irradiation slots are usually published in early April, August, and December. Slots are allocated on a four-monthly basis:

- June to September

- October to January

- February to May

Each month, a set portion of time is allocated for commercial projects, with the remaining slots dedicated to academic research. In some cases, an entire allocation period may be fully booked by commercial projects. Short-term notice slots may become available periodically, so Rapid Access Proposals to be submitted at any time.

To receive notifications about scheduling deadlines and availability, email dcf.experiments@manchester.ac.uk and request to be added to the Irradiator Users list.

Proposals undergo panel assessment, and we strongly encourage an informal discussion before submission. Proposals should be submitted on the most up-to-date form, which is emailed when calls are issued.

Process:

- Contact DCF for an informal discussion before submitting a proposal.

- Outline and agree on experimental activity informally, pending final confirmation.

- Submit the proposal form to dcf.experiments@manchester.ac.uk in response to a call.

- Proposal undergoes technical evaluation at DCF.

- Proposal undergoes scientific review and prioritisation. All potential users will also be expected to review proposals.

- Facility time is allocated based on availability.

Experimental activity is scheduled, and confirmation is sent to the user.

Analytical and characterisation equipment

For analytical equipment bookings, contact dcf.experiments@manchester.ac.uk with details of your experiment and required equipment. Our team will follow up to discuss dates and feasibility.

If you intend to base staff or students at DCF as part of a grant proposal, we strongly recommend consulting us before grant submission. Due to the remote nature of DCF, researchers staying for more than two weeks must have an appointed local line manager at least one month before arrival.

Note: We require at least two weeks' notice to produce letters of support for grant applications.

For a comprehensive overview of our research capabilities, visit our research portal, or explore a detailed article describing our facilities. If you’re interested in collaboration, don’t hesitate to get in touch with our team today.