Fuel and fuel cladding

We work to develop and improve the performance of nuclear fuels and fuel cladding associated with existing and future reactors.

Key contacts

- Tim Abram

- Michael Preuss

This work is supporting an industry-wide effort to maximise fuel assembly reliability, extend burn-up periods and reduce the cost of manufacture. We are exploring how future nuclear reactors can be engineered to the highest standards.

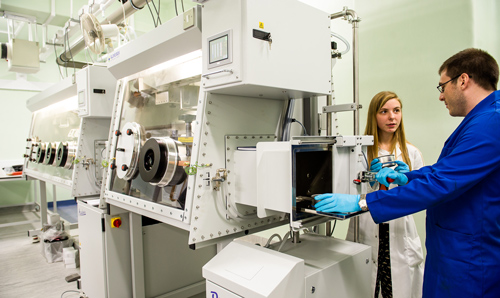

The University of Manchester is the academic host for the UK's Nuclear Fuel Centre of Excellence, providing extensive capabilities for the manufacture, characterisation and testing of uranium and thorium fuels.

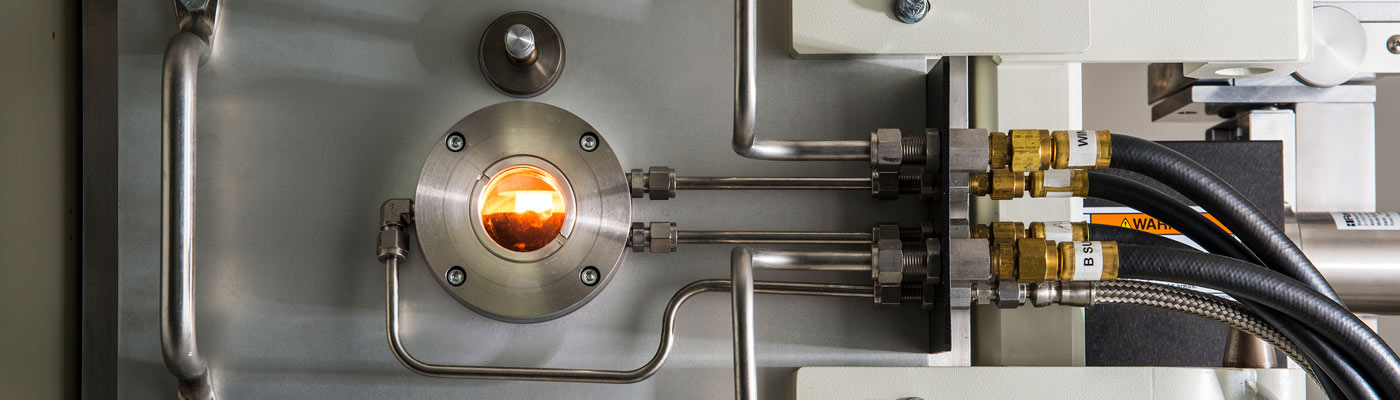

Fuels can be subjected to high temperature oxidation and steam corrosion as well as ion beam and gamma irradiation at our Dalton Cumbrian Facility to examine how the fuels will behave throughout their operational lifetime and under accident scenarios.

Our researchers form the only UK academic group working with representative fuel materials containing uranium and thorium. Work on accident-tolerant fuels is a high research priority both in the UK and internationally.

The University also hosts the world’s largest grouping of academic expertise in zirconium technology. Research into the in-reactor degradation of zirconium-based alloys is at the forefront of work to correlate microstructural damage resulting from neutron irradiation with that produced by ion-beam irradiation.

MIDAS, an EPSRC programme grant lead by Manchester and focusing on zirconium degradation, now brings together the UK activity in this area and will provide new fundamental understanding, which is likely to have a direct impact on safety cases and future materials development.

More information

The following research groups, centres and institutes work within the fuel field:

- Henry Royce Institute

- The Nuclear Fuel Centre of Excellence

- Zirconium technology at the Materials Performance Centre